A roller hearth kiln is a type of continuous high-temperature furnace designed for efficient, uniform, and controlled heat treatment of materials. It is widely used in industries where product quality and production consistency are critical, such as ceramics, advanced materials, and the manufacturing of battery components.

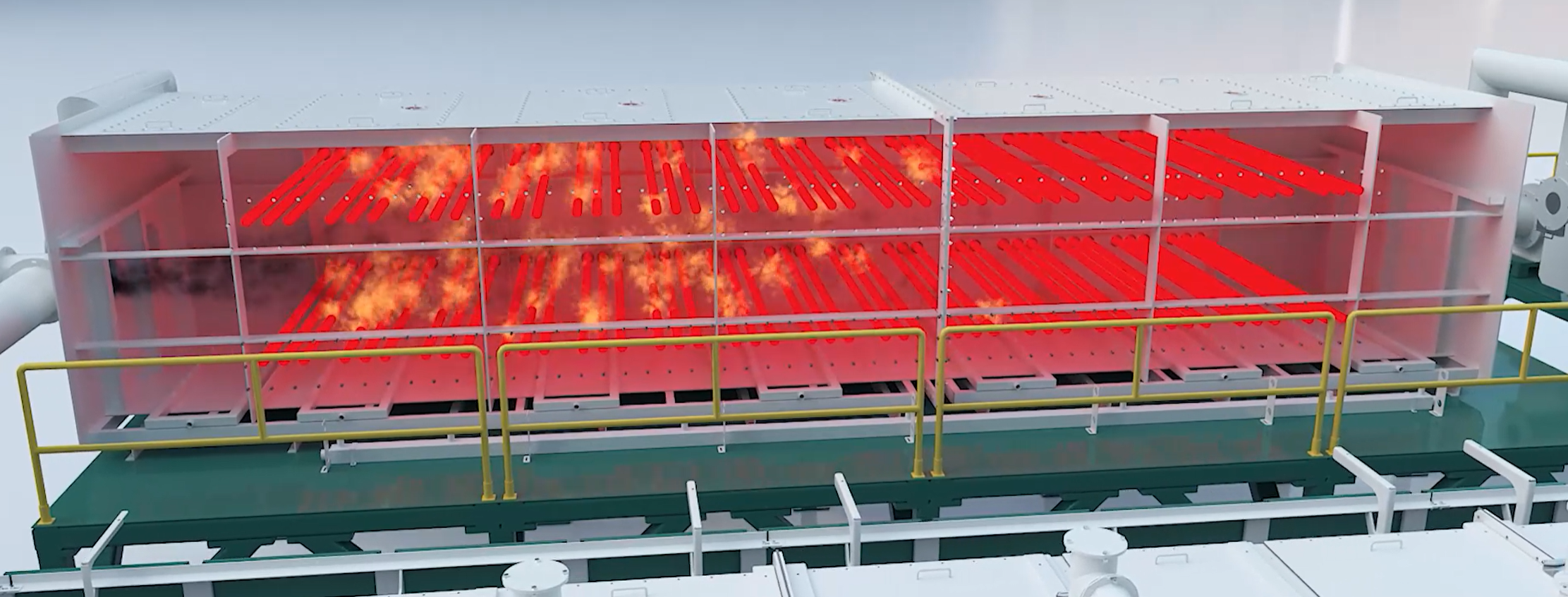

In a roller hearth kiln, ceramic rollers or silicon carbide rollers are installed along the length of the furnace. These rollers continuously transport products through different temperature zones, ensuring smooth handling without manual intervention. The design enables precise temperature uniformity, which is vital for processes such as sintering and material densification.

The kiln’s heating system, combined with a carefully controlled atmosphere—which can be air, oxygen, nitrogen, or a custom gas blend—allows manufacturers to tailor the thermal profile to specific product requirements. This flexibility ensures optimal results for various materials, whether the goal is to achieve a certain crystal structure, remove impurities, or bond particles at the molecular level.

One of the most important uses of roller hearth kilns today is in the production of lithium-ion battery and sodium-ion battery components. These kilns are used for firing cathode and anode materials as well as ceramic powder coatings for separators and other battery parts. The ability to maintain high temperature stability and a clean processing environment ensures the highest material performance, directly impacting battery efficiency, lifespan, and safety.

In the ceramics industry, roller hearth kilns are employed for ceramic powder sintering and the production of advanced ceramics for electronics, energy storage, and structural components. The use of silicon carbide rollers ensures high thermal resistance, long service life, and minimal contamination of delicate products.

Sintering is a key process in roller hearth kilns, where powdered materials are compacted and heated to just below their melting point. This thermal process strengthens the material by bonding particles together. In battery production, sintering improves the conductivity and stability of cathode and anode materials, while in ceramics it enhances density and mechanical strength.

A roller hearth kiln is more than just a furnace—it is a precision thermal processing tool that combines efficiency and product consistency with the ability to handle complex materials under controlled atmospheres. Whether producing advanced ceramics, lithium-ion battery, or sodium-ion battery components, the roller hearth kiln remains an essential piece of equipment for industries that demand high product quality and repeatable results.